FILTERS

The best filtering material for personal protective equipment

UFI Filters face masks guarantee complete protection thanks to the efficient filtering media they contain, produced with Meltblown technology. Laboratory tests carried out by Polytechnic University of Milan have recognised UFI Filters’ polypropylene Meltblown as one of the best on the market for face masks.

Meltblown

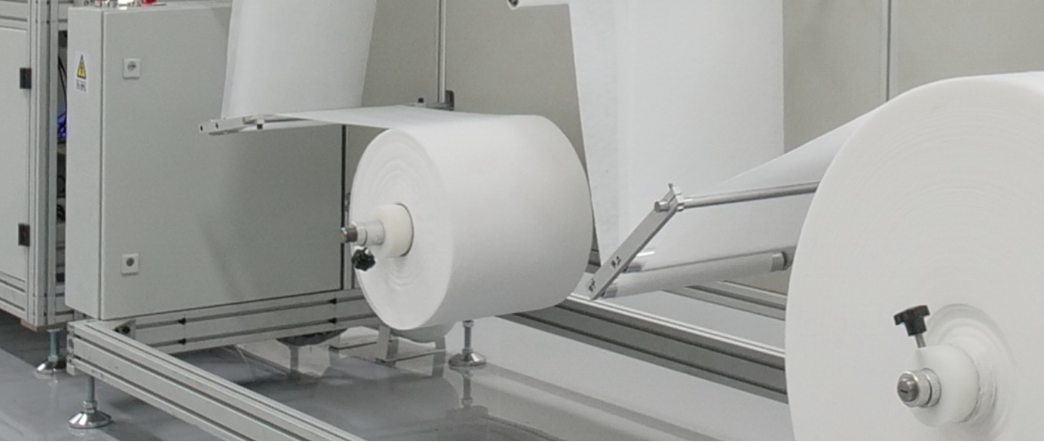

UFI Filters has been committed to the in-house production of filtering materials since the ‘90s, and Meltblown is one of its star products, the outcome of its considerable experience in the world of automotive filtration for the leading international car manufacturers. Thanks to its know-how and continuous technological investment in state-of-the-art machinery, UFI Filters can count on a notable production capacity for Meltblown, the non-woven fabric with a bacterial filtration efficiency (BFE) of over 95%.

UFI Meltblown, the fabric produced by UFI Filters suitable for different types of masks

UFI Filters’ Meltblown TNT was developed for the first time in Italy at the Ala di Trento UFI Innovation Centre – the research centre that develops innovations in collaboration with the leading Italian universities. Today, the Group’s factories around the world make different types of Meltblown with different thicknesses and permeability, suitable for the production of medical, FFP2 and FFP3 face masks. Each type has been tested according to the international standards UNI EN 14683: 2019, UNI EN 149: 2009 and UNI EN13274 for filtering efficiency, and according to ISO 9237:1995 for breathability.

UFI Filters collaborates with other companies, which have already chosen the best protection of UFI Meltblown.

The different types of UFI Meltblown

UFI Filters’ Meltblown TNT was developed for the first time in Italy at the Ala di Trento UFI Innovation Center – the research centre that develops innovations in collaboration with the leading Italian universities. Today, the Group’s factories around the world make different types of Meltblown with different thicknesses and permeability, suitable for the production of medical, FFP2 and FFP3 face masks. Each type has been tested according to the international standards UNI EN 14683: 2019, UNI EN 149: 2009 and UNI EN13274 for filtering efficiency, and according to ISO 9237:1995 for breathability.